1. Delta Cup 2021 - A motivation to display an engineer's skills

Planted December 19, 2021

Before checking out this post please look up the Projects Section to get an overview of my work. Why do you think I express the Delta Cup as a test to an engineer’s skills? It is because, according to my opinion, Practical knowledge is a key asset for a person to be recognized as an engineer. But don’t take me wrong I am not against theoretical knowledge. Theoretical learning is a foundation to any concept but to know whether it can be practically applied or not is a point of discussion.

Delta Cup is a competition organized by Delta Electronics. The Contest is hosted by the Chinese Association of Automation (CAA) and sponsored by the Chinese Association of Automation, and the Industry and Information Industry Vocational Education Teaching Steering Committee under the Ministry of Education. Every year they keep various tracks for the competition and this time they had “Innovative Machines”, “Smart Factory”, or “Better Future Living”.

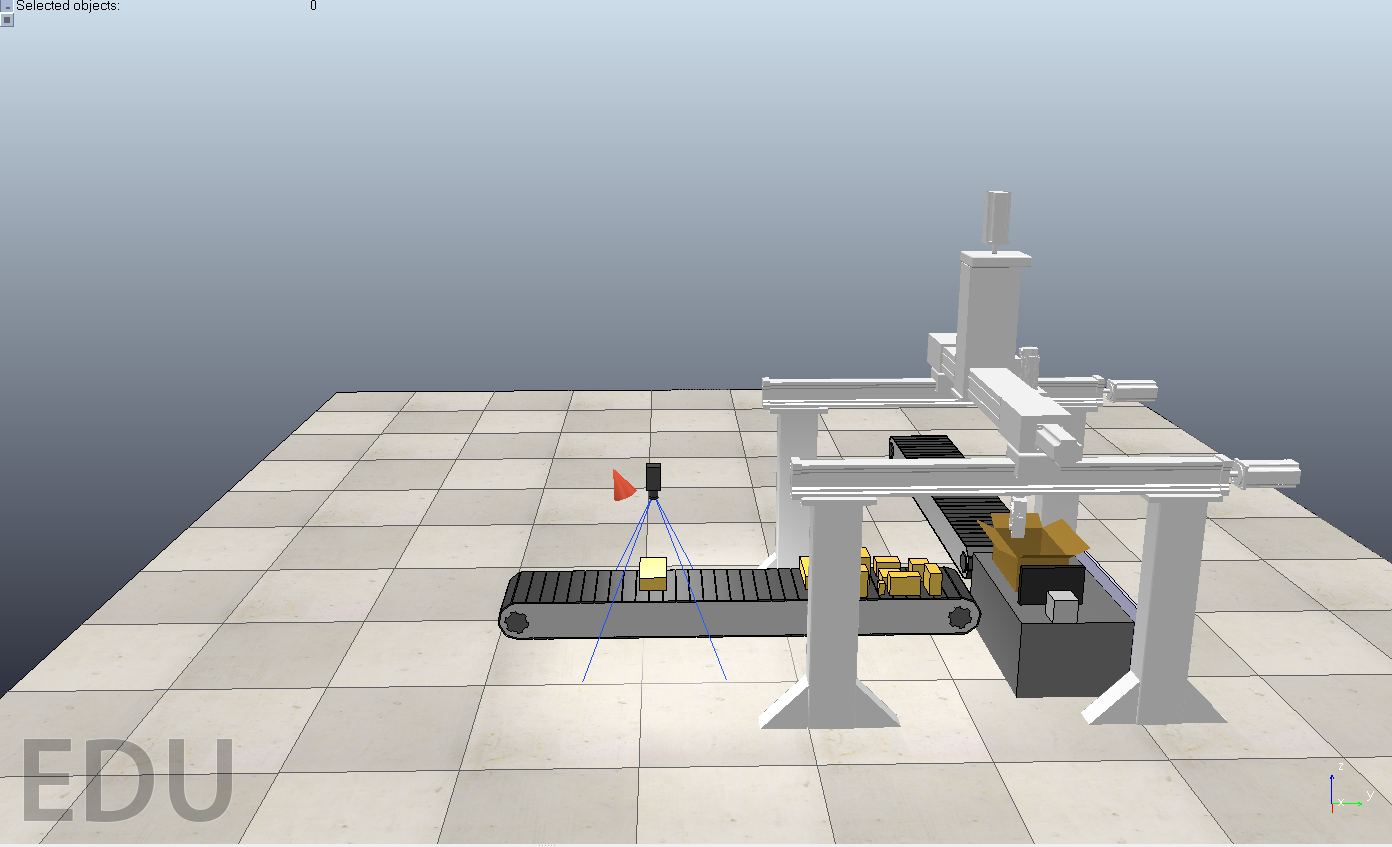

Now it all commenced with a slight push from seniors at SRA for participating in the competition. Dhairya Shah, Ninad Jangle, and I formed a team. Initially, we began to ponder about the ideas. Several ideas were rejected due to their cons on the practical side. We finalized our idea of pick and place bot under the “Smart Factory” track and built a still model in simulation and made a rough list of Delta products that would be apt for the model. Mr. Alister D’Silva, from the Delta side, was mentoring teams from the Mumbai division. He reviewed our idea and suggested his viewpoint and advice on the same. We implemented the changes and addressed the problem and solution in the proposal.

In May, the result was out. We were startled to hear that we got selected for the international level competing with 100 other teams and were one of the two teams representing the Indian Division!! So, our immediate next step was to finalize the Delta products list and distributing the work. Dhairya and Ninad handled the 3D Bin Packing algorithm for efficient packing and automating the bot by controlling it using PLC and HMI. I took control of the Mechanical designing and fabrication of the bot.

As we had only 2 months, the workload was immense. Building up the structure was our main challenge as we were naive in that field. Prof. Faruk Kazi was our mentor. He assured us funding from our college for the setup and assisted us in solving problems from the college side. Because of him, we met Dr.Sangram Patil who was himself a Ph.D. passout from VJTI. He had a mechanical background and his mentorship and support helped us in constructing the bot even faster. He helped us in simplifying the design and his one piece of advice was “Due to the time constraint, go with standard structures while designing and choose a material which has a good supply and which has the capability of handling loads”. He connected us with his friend Mr. Amit Ajmera who came to our rescue. He introduced us to various types of machines, manufacturing problems. I got the opportunity to view the laser cutting machine and hear about its working. And under his supervision, all the work was done.

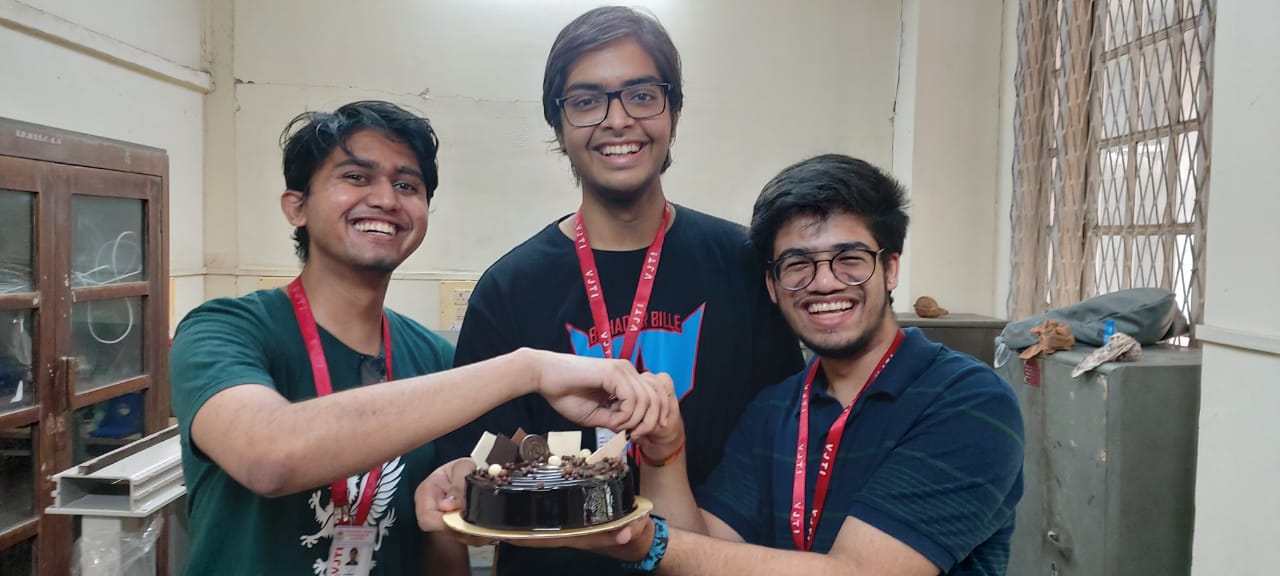

After a lot of hard work and many sleepless nights, we were able to finally complete the design and successfully manufacture, though we weren’t able to automate the bot due to the time crunch we tried to present a polished product to the judges. We bagged the 2nd prize category and were extremely overwhelmed by the experience we had. I am never going to forget these 3 months of my life ever, as they taught me that it’s easy to imagine but it’s a lot harder bringing it to reality.

Problems Faced

- In the month of April and May, Covid 19 cases were at its peak here in Mumbai. So we had to take risk and move out to get our work done.

- Industrial production rate were significantly reduced. So there were delays in transportation of parts.

- Handling people and explaining the process of implementation.

Our Experience and Learnings

- Software, hardware side, technicalities of the industrial robots, automation equipments like PLC, HMI

- Mechanical production and manufacturing in the industry

- Time, money and resource management

- Team Bonding and building connections

- Practical stuff is time consuming and experienced real world problems

Special thanks to: VJTI, COE-CNDS VJTI, SRA VJTI, Omkar Bhilare, Saad Hashmi